Both millwrights and EM technicians have similar jobs when it comes to physical labour but are actually quite different if looked at closely.

Continue readingA Day in the Life of a Millwright: What You Need to Know

Are you thinking about taking up a career of Millwrights in Canada? Well, if you are, here are a few things you should know about this career path before jumping in.

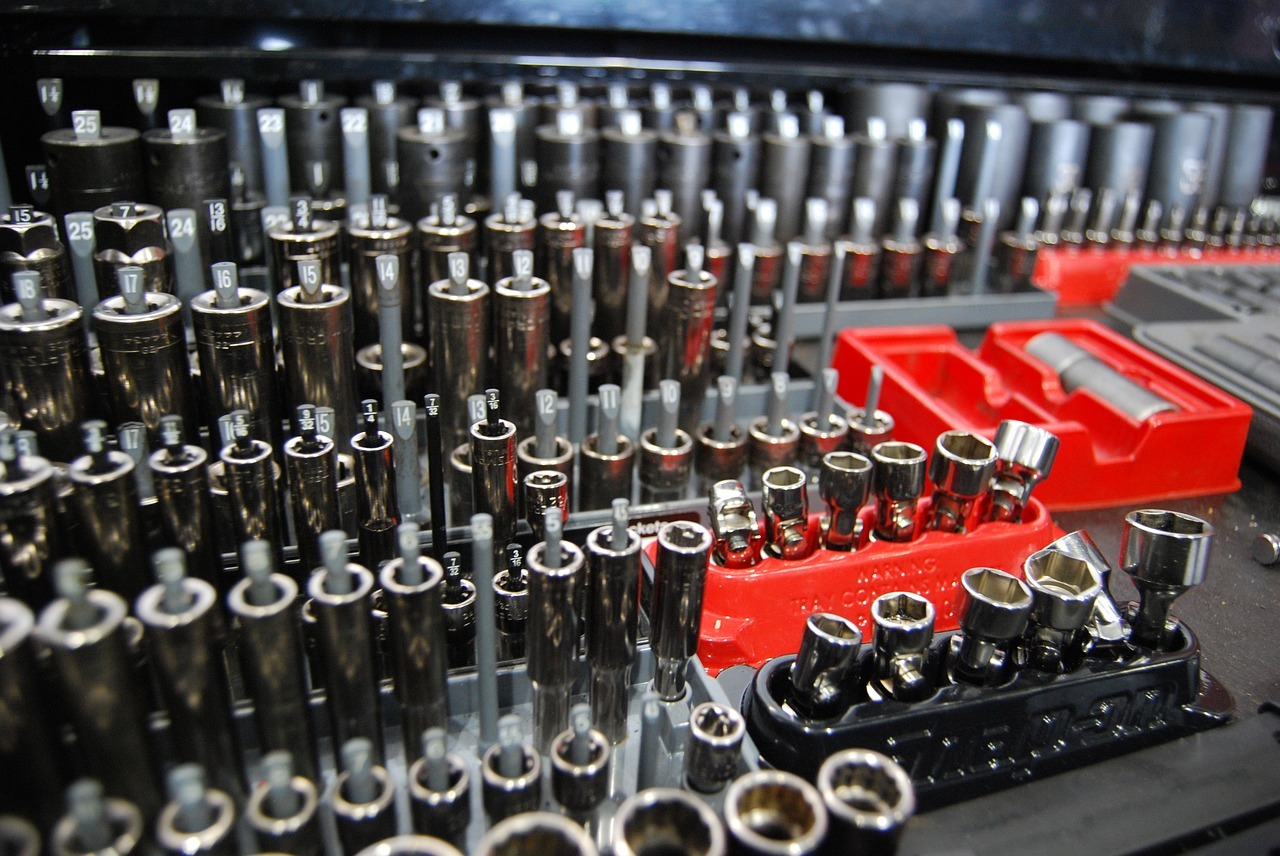

Continue reading15 Millwright Tools That Every Journeyperson Should Carry in Their Toolbox

You never know which millwright tools you will need on the job. Hence, We put together a list of the bare essentials that can help you with most jobs.

Continue readingHow to Become a Millwright in Canada: An Industry Overview

How to Become a Millwright in Canada: An Industry Overview

Before we dive into the matter of how to become a Millwright in Canada, we first have to understand what a millwright does. We need to get a holistic understanding of the pay grade that they face in the industry, the work conditions, and so on. To begin, a millwright’s primary responsibilities include assembling, installing, dismantling, and just working with heavy machinery of all types.

Typically, they work with very advanced machines in commercial manufacturing industries such as power generation, mining, construction, food processing plants, and even the automobile industry.

The Different Types of Millwrights and Millwright Licenses

There are essentially two broad classifications of millwright licenses, according to Michael Samson, an accounts manager, and recruiter at Pure Staffing Solutions. In an interview, he revealed that these categories are Industrial Millwrights which carry the license 433A and the other one is 426A, which is a Construction Millwright.

“Industrial Millwright 433A can work in any industry across Canada. The construction millwright is more specifically a certified program, designed for construction sites and other such work environments like power plants, the marine industry, and so on,” said Samson.

He went on to elaborate how there are also higher levels of classifications that specify where in Canada you can work. “There are two types of millwright categories, one is a Red Seal Millwright and then there are Journeyman Millwrights. The Red Seal Millwright is an interprovincial Millwright License. If someone has a Red Seal License can work anywhere in Canada. The Journeyman Millwright License holders can only work in certain provinces. E.g. if someone got a Journeyman License in Ontario, they can work only in Ontario.”

Samson went on to explain, “However, if the Journeyman Millwright knows the National Industry Standards, and they take an exam, they could qualify to work in other provinces as well. They will be given a Journeyman Red Seal License.”

“The best way to predict the future is to create it.” – Abraham Lincoln, 16th President of the U.S.A

The Average Salary You Can Expect

The average pay for an industrial Millwright in Canada is $65,496 per year which comes to about $31 per hour. However, when we look at the Salary range, it can start anywhere from $47,000 per year to $80,000 a year. New apprentices who are just starting, get paid at the lower end of the pay scale. Once they get their licenses, it goes towards the higher end.

New millwrights also get an average bonus of $1,146. Keep in mind that it varies from company to company, some offer a signing bonus and some offer profit sharing.

As an example, Pure Staffing Solutions has one client who offers a $1,500 signing bonus and once they complete one year they get another $1,500. The commercial Automobile industry is a prime place for high salaries as they pay an average minimum of $40 per hour, one of the highest pay rates that a millwright can get in the country.

Becoming a Millwright Canada

There are a few different ways to go about it, if you are wondering how to become a millwright in Canada. While formal education isn’t the hard and fast rule, it does give you a significant advantage. The same is true of apprenticeships. While it is not necessary, it does equip you with a certain set of skills that allow you to gain a stronger career footing in the industry.

“Do what you love and success will follow. Passion is the fuel behind a successful career.“ – Meg Witman, American Business Executive

Education

If you are taking the educational route, you need a minimum qualification of a high school degree or equivalent to get a job as a millwright. Having this means that you would be eligible to study higher, get the prerequisite training and write the exam in your quest to becoming a millwright in Canada.

Apprenticeships

This method goes hand-in-hand with education. If you want to work as a licensed millwright, then you need to do an apprenticeship. Samson explains it as follows, ” Once they have they (millwright aspirants) will be eligible to complete Millwright training. Typically, a Millwright completes 3 to 5 years of apprenticeship (in-field work and classroom studies). Also, each year of instruction includes 144 hours of technical instruction and up to 200 hours of paid, on-the-job training throughout the apprenticeship.”

“We’re here to put a dent in the universe. Otherwise why even be here?“ – Steve Jobs, Co-founder of Apple

Working Without a License

If you are not inclined towards the apprenticeship or educational path, you can always work as an unlicensed millwright. You should note that it is optional to have the license, but carrying one does have its perks.

“Even if you haven’t completed an apprenticeship program, but have hands-on experience and have worked with a company as an unlicensed Millwright you can challenge the exam directly and get the license,” said Samson.

Samson added, “Someone can work without a license, but if you have a license, your value in the market goes up. For example, some of our clients offer a bonus of an additional $1 or $2 on top of the industry standard for Millwrights with a Red Seal License. If you don’t have the license, you will only be paid the industry standard.”

Conclusion

At the end of the day, the choice is on you. When the question of how to becoming a millwright in Canada arises, the path is straight forward. It has a lot of benefits and even more so if you are fully qualified. Given the country’s booming industry and high levels of demand for skilled workers in this field, employment is not scarce. However, the competition is high.

Therefore, even if the path to becoming a millwright in Canada is quite straightforward, you need to be able to beat out the competition. That is where we come in. At Pure Staffing Solutions, we help you identify and get placed in the best companies. So, if you truly want to give it a shot, get in touch with us and get your career started!

Recent Posts

Women in Skilled Trades: Breaking Barriers and Shaping the Future

Remote Work Revolution: Adapting Recruitment Strategies for a Digital World

Breaking Into the Tech Industry: Skilled Trades Jobs in Canada’s Tech Boom

Expanding Your Horizons: How Canadian Employers Are Seeking Global Talent

The Art of Negotiation: Tips for Securing the Best Contract Terms as a Skilled Worker

The Future of Manufacturing Jobs in Canada: Trends and Predictions for 2024

Heavy Machinery Maintenance Tips: A Millwright’s Guide

Heavy Machinery Maintenance Tips: A Millwright’s Guide to Success

When it comes to the commercial industries, be it manufacturing units, mining projects, or what have you, none of them wants to experience downtime. They say time is money, and unplanned downtime comes at a huge financial cost to these companies. This can lead to a ripple effect of several bad outcomes such as loss of faith by clients, loss of money, or even loss of your competitive edge. Therefore it is always important to have a heavy machinery maintenance program in place!

When it comes to heavy machinery maintenance, it can be an expensive affair, to say the least. Anything from just a few replacement parts can put a dent in the budget, as these are specialized components. However, in the long run, this maintenance will save you a fortune. In this article, we will explore how as a millwright or as a business you can employ certain measures to extend the life and performance of your heavy machinery.

Heavy Machinery Maintenance Tip #1: Always be Proactive

No matter how powerful and advanced your heavy-duty machines are, they require some level of basic maintenance to run smoothly. Implementing a regular and proactive approach to maintaining it, is the key to sustained operations. This will reduce your downtime and help minimize unexpected malfunctions down the line. As the saying goes: “Prevention is the best cure.”

Heavy Machinery Maintenance Tip #2: Have Preventive Measures in Place

Picking up on the previous tip, you need to ensure that there is a preventive maintenance program in place. This program should be able to keep a regular schedule as well as anticipate wear and tear over time. Taking continuous action before it is needed will ensure that your machines are performing smoothly without any unexpected breakdowns. This drives up reliability.

As a part of this step, you need to incorporate regular inspections and parts replacement. Everything has a shelf-life, even mechanical parts.

Check that and replace accordingly. Don’t wait till the last minute. The bonus of having preventive heavy machinery maintenance in place will also get you higher resale value when you want to upgrade.

Heavy Machinery Maintenance Tip #3: Avoid Exceeding the Performance Specs

All machines and their parts come with performance and use-specifications. Factors such as maximum load capacity, range of operations, pressure, temperature, and other limits should be taken into consideration. Check the operator’s manual regularly, use it as a checklist and ensure that the machine is well within its limits. This will help drive down wear and tear and give it a longer life.

Additionally, it can also prevent workplace injuries and accidents. We know all too well how dearly workplace injuries can do to your business, financially or reputation-wise. Do you know those user manuals that come with your new television that none of us bothers to read? Well, there is a reason they include those. Those manuals have everything you need to keep things running smoothly.

“Preventive Maintenance: Don’t start today by doing yesterday’s work.“ – Deniece Schofield, Author

Heavy Machinery Maintenance Tip #4: Get a Millwright on Your Team

This is where having the expertise of Millwrights in Canada comes in. Without a deep and detailed understanding of the industrial machine and all its parts, you can’t do any proper maintenance. The same goes for devising robust maintenance programs. Millwrights who have undergone training, and have some experience under their belt make all the difference when it comes to understanding machines.

This is one of the main reasons that their talents are so coveted for heavy machinery maintenance.

Heavy Machinery Maintenance Tip #5: Train Your Employees

This may seem obvious, but it needs to be said. Untrained workers in a place that depends on heavy-duty industrial machines can prove to be a disaster. The work productivity aside, the sheer safety risk that it brings to the table should be a concern enough for any business. So, train your employees and invest in it. Additionally, you should also hire experts in heavy machinery maintenance, such as Millwrights.

At Pure Staffing Solutions, we recruit and place some of the best Millwrights in Canada for our clients. We take pride in equipping businesses with competent contractors who always get the job done.