A Day in the Life of a Millwright: What You Need to Know

Are you thinking about taking up a career as a Millwright in Canada? Well, if you are, then you are in the right place. Millwrights, also known as millwright technicians or industrial technicians, are craftsmen who work with equipment and machinery. More specifically, their job revolves around installing, dismantling, moving, calibrating and fixing heavy industrial machines and equipment. They have to work with complex machinery on a day-to-day basis. Millwrights also have to do it with precision and oftentimes in stressful or risky conditions.

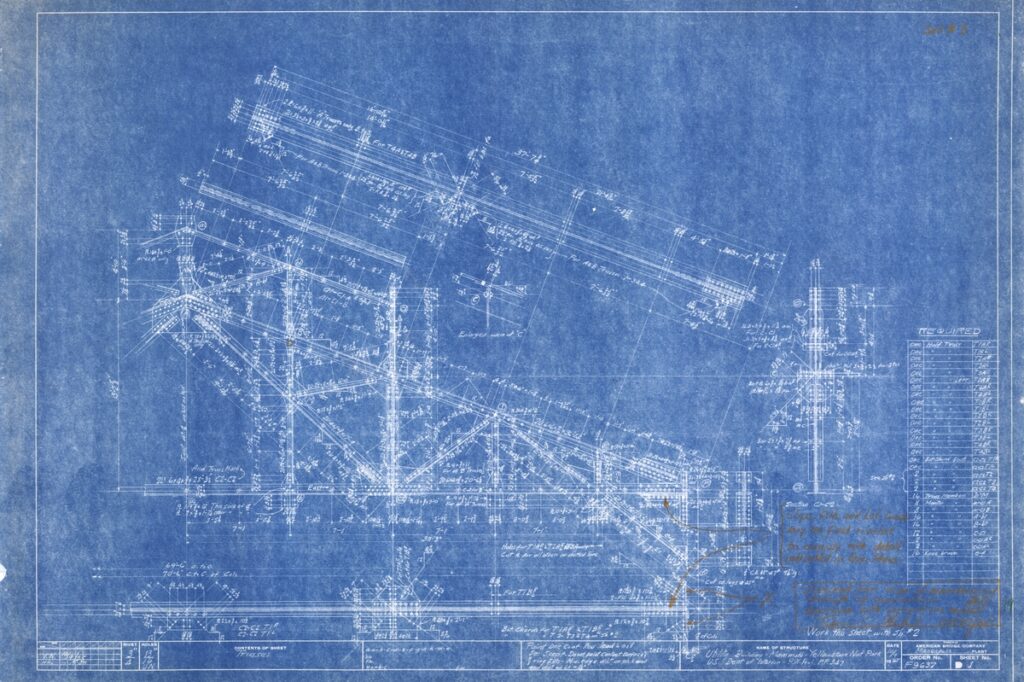

Being a millwright does have its fair share of risks. However, it’s often more about coming up with solutions to complex problems. This means there is a ton of planning, blueprint reading and creativity involved in this line of work. If this is something that you are passionate about, then you’re off to a good start with this blog. In this article, we will walk you through a typical day in the life of a millwright so that you have an idea of what you could expect down the line.

Table of Contents

ToggleAttending Your Morning Meetings

As we mentioned before, the work a millwright does can carry with it a lot of different elements. This includes varying environments, new challenges and so on. To meet the challenges of the day, each day you will usually have a meeting with your supervisor or manager. Together you will run through the safety issues and toolbox checklist. In the industry, this is often referred to as a ‘toolbox talk’.

This is also when the supervisor will give you and the rest of the crew about the safety checks in place and any potential safety risks they might have observed at the worksite. After everyone is briefed, there is usually a registry for all the crew to sign to show that all working personnel were at the meeting and understood the risks, the job, what they need to do and so on.

Communication is the first and biggest step before beginning any new project as a millwright.

Going over the Blueprints and Plans Thoroughly

Continuing along the same lines as the previous point, planning is everything as a millwright. Before you begin any project, the millwright needs to go over the plans or blueprints with the supervisor to establish what is expected of them and what work needs to be done.

This is also around when you would be selecting the right tools for the job. Remember, as a millwright technician, you have a myriad of tools at your disposal.

Knowing how to read and analyze blueprints is an important skill to have if you want to be in this profession. Millwrights work with a wide range of different machines that can be found in varying industries. Hence, preparation and execution go hand-in-hand.

Getting Down to the Job at Hand

Once you get to the worksite and have all your tools ready, the work can begin. Usually, millwrights might begin by inspecting the machine and labelling all the equipment they need to fix or work on. In this line of work, collaboration and teamwork also play an important role. It not only makes for a safer work site but helps you in your quest to find that perfect solution to a complex problem.

Daily tasks could include any number of things from calculating and measuring to welding, machining parts, operating heavy machinery, rigging, repairing, installing, moving, and so on. Fair to say that this isn’t an office job. Keeping in mind that there is a lot of physical labour in this career, it might not surprise you to learn that a lot of millwrights often have a group stretching session before they start the work. The last thing you want is to get a cramp while operating heavy machinery.

“The expert at anything was once a beginner.” – Helen Hayes, American Actress

Working Hours for a Millwright

This depends on the contract you signed up with, the industries you work in and your company. It could range from a typical 8-hour shift to well past the 20-hour mark if there it is a time-sensitive project. When it comes to heavy industrial machines, you have to keep in mind that, every minute it isn’t operational, the company in question is bleeding money. To be in this line of work, you will have to remain flexible with your time. It should also be noted that each project moves at its speed and no two projects will be the same in terms of how many hours you put in.

Equipment That Millwrights Might Use on a Day-to-Day Basis

As we mentioned earlier, a millwright is someone who installs, repairs, upgrades or relocates industrial machines. Some of the standard equipment you might use to perform these tasks includes forklifts, scissor-lifts, rigging, come-a-longs, drills, welding tools, saws, hydraulic rams and lifts, etc. It is usually the foreman’s responsibility to make sure that all the on-site journeymen and apprentices have the tools they need to get the job done.

“The future belongs to those who believe in the beauty of their dreams.” – Eleanor Roosevelt, Former First Lady of the United States

Essential Skills a Millwright Needs

Now that we have gone over some of the basics of what a millwright might do on an average day, let’s have a look at some of the essential skills they might employ. The first, a most essential one, is noticing potential hazards. The safety of the work environment is paramount for industrial technicians.

Speaking of hazardous scenarios, you would need to be able to read, interpret and apply the data from Material Safety Data Sheets (MSDS). These documents have all the information you need when handling hazardous equipment, personal protective equipment (PPE) and first aid procedures.

The next skill is the ability to select the right tool for the job. Let’s narrow it down. As a millwright technician, you need to be able to select the right rope to lift a load. This can be a vertical lifting rope, a choker hitch or a basket hitch. You also have to cross-reference it with the performance series table that will indicate the rope’s size that correlates with the maximum load weight it can hold.

Having said that, numeracy is a crucial skill to have in this job. Millwrights need to be able to take accurate measurements and do calculations on the spot.

You should also note that as a millwright there are two basic tickets or licenses that you can fall under. You can either fall under ticket 433a or 426a. The 433a ticket categorizes Industrial Mechanic Millwrights who install, maintain, repair, and remove stationary industrial machinery, mechanical equipment, and automated and robotic systems. These millwrights mostly work in industrial plants and factories.

The 426a ticket refers to Construction Millwrights who install, maintain, and troubleshoot industrial machinery, mechanical equipment, and other automated and robotic systems. the key difference is that these millwrights serve the construction industry primarily. They also work closely with other tradespersons like electricians and pipefitters.

In Summary

Yes, the millwright profession is a hard one but can be incredibly rewarding. For one, it is not a sedentary lifestyle. It also requires that you employ both physical and mental effort daily.

More than lugging around heavy machines, this job is about careful calculations, combined with expert trade skills to get the project done. And above all else, this job requires that you pay attention to safety every second of the day as long as you are at the worksite. If you are thinking of going down this road, check out our other article on how to become a Millwright in Canada.