15 Millwright Tools That Every Journeyperson Should Carry in Their Toolbox

The profession of a millwright in Canada or any other country for that matter is never uniform. What we mean by that is, no two jobs are ever the same. Work procedures, problems, solutions all vary from project to project. That is why it helps for a millwright to be prepared for every task. This is where having the right millwright tools in hand comes into play. In today’s article, we take a little bit of a side road and explore what some of the most important tools are for a millwright to have in their toolbox.

Keep in mind that as a millwright you will need to have a whole mountain of tools with you; such are the demands of the job. If we were to list them all, we would be here all day. Hence, we have taken the liberty of sorting out a list of the essentials that you should always have on hand. These tools can be used for a wide array of jobs and problems and they cover the necessities of most projects.

Table of Contents

Toggle1) Safety Glasses

The reason that glasses take the top spot on this list is that safety comes above all else. No matter the job, you cannot do it right if you don’t have the right safety gear in place. Safety glasses protect your eyes from all types of flying debris. Just make sure that they are high quality and comfortable as you will have to keep them on from the time you enter a job site, up until you leave.

2) Work Gloves

Continuing on the previous point of safety equipment, work gloves play an essential role. When you are working with heavy machinery, sharp objects, and so on, you need to protect your hands. Much like a doctor, your hands are your biggest tools, so take care of them. Many of the Canadian millwright colleges recommend leather gloves or a combination of hiding and Suede gloves for optimal protection.

3) Screwdrivers

Like any tradesman that works with machinery, fittings, and so on, screwdrivers are as basic as they get. They can be used for a variety of jobs and are very important. As far as these millwright tools go, you need a set in your toolbox. Consider getting Phillips as well as flat head screwdrivers in your set. You could go for something with different sizes or even get a single one with interchangeable heads.

4) Tape Measure

As a millwright, the position and alignment of machines are a core part of most projects. If something is not exactly where it is supposed to be, then the results could prove to be disastrous. A simple tape measure can go a long way in helping you get the job done more accurately.

“It is essential to have good tools, but it is also essential that the tools be used in the right way.“ – Wallace D. Wattles, American Writer

5) Combination Wrenches

Coming to yet another set of important millwright tools, we have combination wrenches. They come in a variety of different sizes and can help you tighten or loosen nuts and bolts on machinery. Make sure that you get the whole set and carry that with you on every job. You never know which size you might need.

6) Socket Set

A socket set is similar to the combination wrenches, in that, it helps you tighten and loosen nuts and bolts on machines. The only difference is the socket set and socket wrench work in tandem to give you better leverage and are easier to use than traditional wrenches. Given the wide array of sockets that come in a set, you can be more prepared for the job. This makes these millwright tools a must-have!

7) Allen Set

Allen Keys or Hex Keys as they are sometimes called are ideal millwright tools that aid in the tightening or loosening of hexagonal bolts or other compatible fasteners. Yes, it does come under the socket family and yes, it is an essential tool as you never know which part of what machine you might need to put together or take apart.

“Give ordinary people the right tools, and they will design and build the most extraordinary things.“ – Neil Gershenfeld, American Professor

8) Utility Knife

A utility knife can be very useful, it’s practically in the name itself. Millwrights can use this knife for a wide range of different things, from marking something to opening packages and even just scraping glue off old parts that need to be re-fitted.

9) Flashlight

A major part of the millwright’s job involves the active diagnosis of the issue at hand. You need to inspect any machine before you can get down to fixing it. This can prove to be tricky if you have to look at a part that is obscured or not well lit. Having a durable flashlight can make all the difference and save you a ton of time. You don’t want to waste hours upon hours taking a piece of machinery apart just to find that the issue was in another place.

10) Assorted Levels

Be it a machinist level or a Torpedo level, you need to have this on hand. If a piece of machinery is not level or a fixture is off just by a few centimetres, that can be bad in the long run. Having these levels ensures that you maintain quality control and that machines work well in conjunction with each other. Another alternative is using a Plumb Bob. A traditional level may not always be the right fit for a millwright’s needs. These devices are easy to work with and give highly accurate results.

11) Needle Nose Pliers

We once again come to the issue of hard-to-reach spots. A millwright’s main goal is to ensure that precision is always present in every part of the machine. Sometimes the human fingers are either too delicate or too clunky to fit in small spaces. Needle Nose pliers can work as an extension of your fingers and help you reach those tight spots.

“Even the simplest tools can empower people to do great things.“ – Christopher Isaac “Biz” Stone, Co-Founder of Twitter

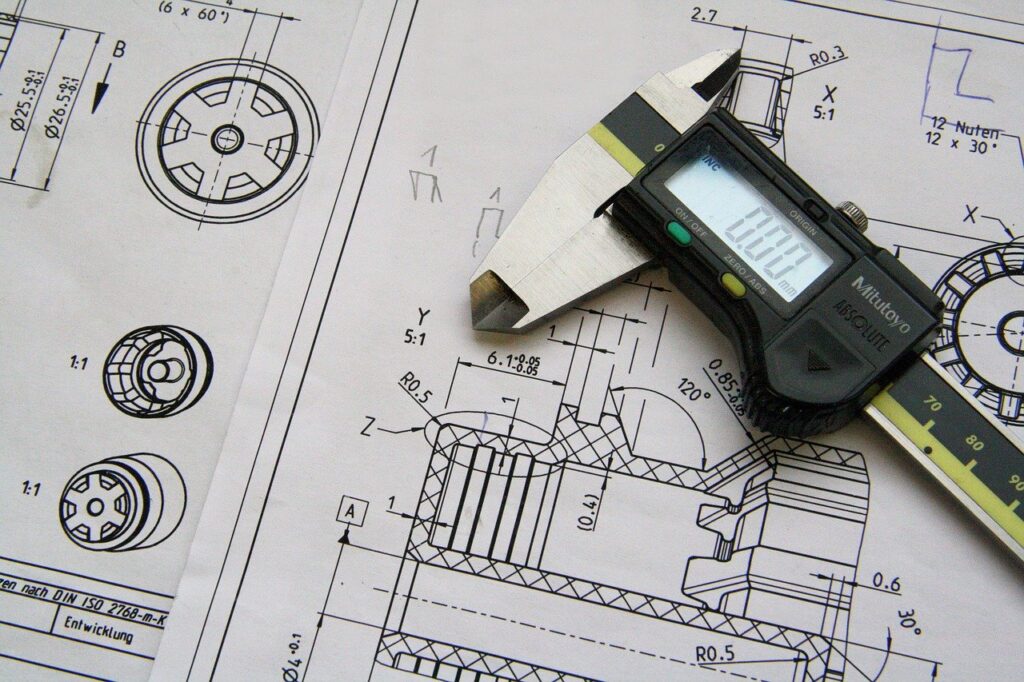

12) Calipers

These are unique millwright tools that help the journeyperson measure things. Unlike your traditional scale or tape measure, this device helps measure tiny machine parts. It aids you in transferring measures from schematics and drawings. You just have to decide whether you would prefer a manual caliper or a digital one, which is easier to work with but costs a little more money.

13) Combination Square

Staying within the topic of measures, we have the combination square. This is a pretty basic and simple tool. It is a ruler with an interchangeable head. The square can be used for measuring a 90-degree angle where necessary. Just be sure to buy one that is small enough to fit in tight spots.

14) Micrometer

Coming to the final item that falls into the category of scales and measures, we have the micrometer. These millwright tools help address problems on a micro level, literally. Some of the measures you might need to take could be minuscule. A micrometer is an ideal tool for calibrating small measures. They allow for the highly precise measurement of any item that fits between the anvil and spindle of the device. Standard micrometers can be used for the measurement of items under one inch in length, depth, or thickness.

15) Tin Snips

Lastly, we have the tin snips. Essentially, these are industrial strength scissors that are used to cut sheet metal, hence the name. These millwright tools make it easy for the user to get just the right amount of power and tension they need to cut through metal such as steel up to 24-gauge cold-rolled steel, or even 26-gauge stainless steel. Given the nature of this tool, it does get worn down quite fast and needs to be replaced regularly over time or sharpened. Make sure you buy a high-quality pair that will last you for a good amount of time.